Repair and maintenance management system

BPMS based products

High adaptability, speed and proper performance of Netrise BPMS will enable the construction and design of any system requirements in organizations.

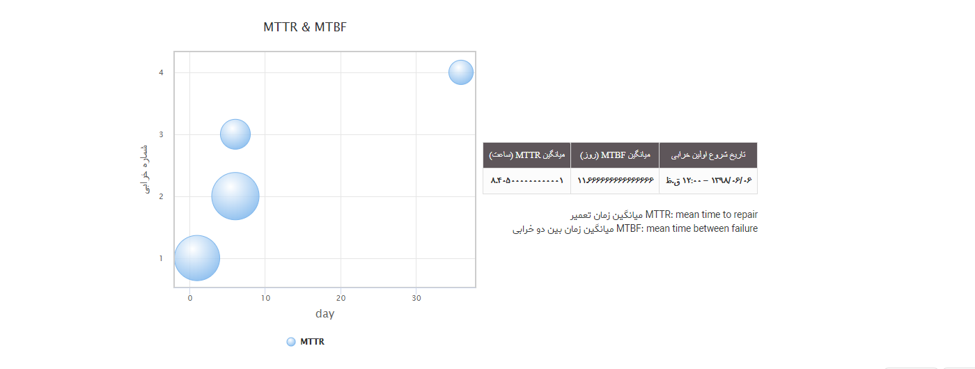

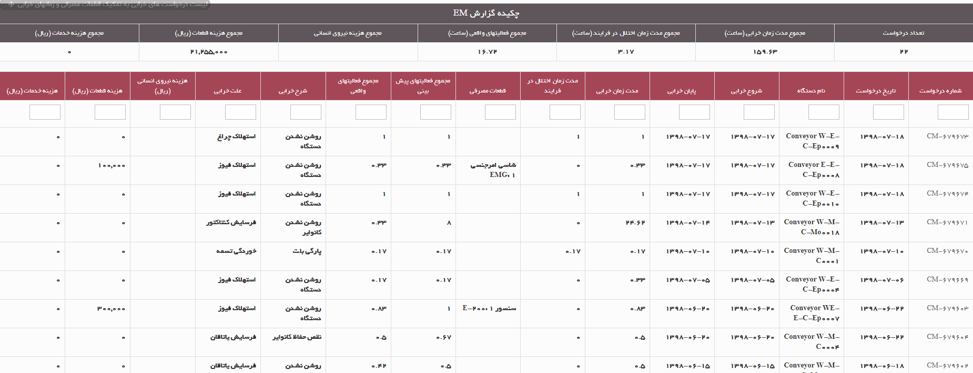

Repair and maintenance management system (Maintenance Management System) which is abbreviated as MMS, the possibility of registering the specifications and ID of the equipment, implementing Automatic requests for preventive maintenance (PM), registration and control of repair history of devices and consumable spare parts, the possibility It provides a variety of reports and graphs including MTTR and MTBF and online equipment monitoring on maps.

The different parts of this system are:

- Definition of types of repair activities

- Defining and structuring the equipment including coding, determining the degree of importance, determining the location and creating a hierarchical structure of Equipment

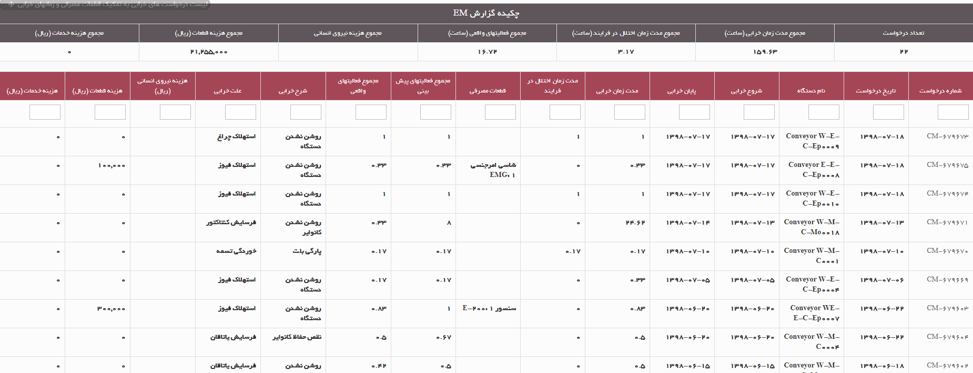

- Calculation of expenses based on person-hours of manpower, number of consumed parts and services performed

- Defining types of strategies and list of PM tasks including review thresholds, preventive activities and consumable parts Need

- Definition of description and causes of failure based on equipment

- Predicting repair activities as a guide to carry out activities by technical forces

- Possibility of connecting to purchasing and service systems for consumable parts and providing services by contractors outside the organization

- The possibility of various notifications such as email and SMS in different parts of the process and based on the importance of the equipment

- Possibility of connecting to warehouse systems and determining the amount of used parts

Some features of this system are as follows:

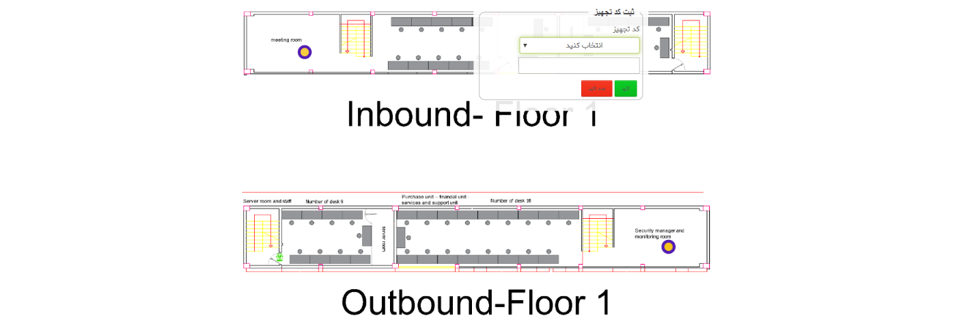

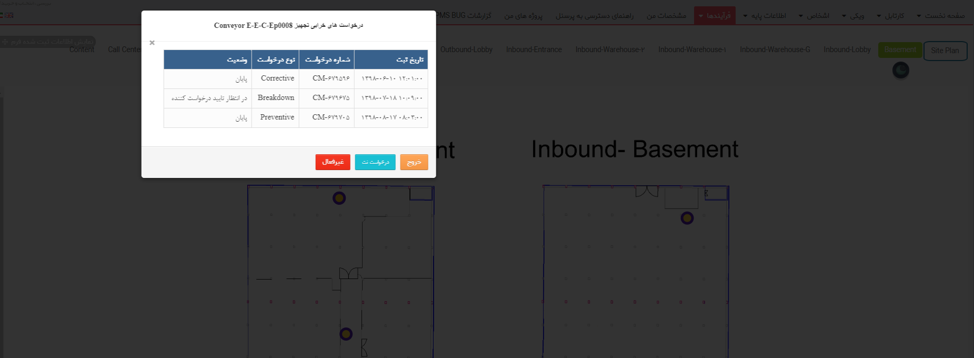

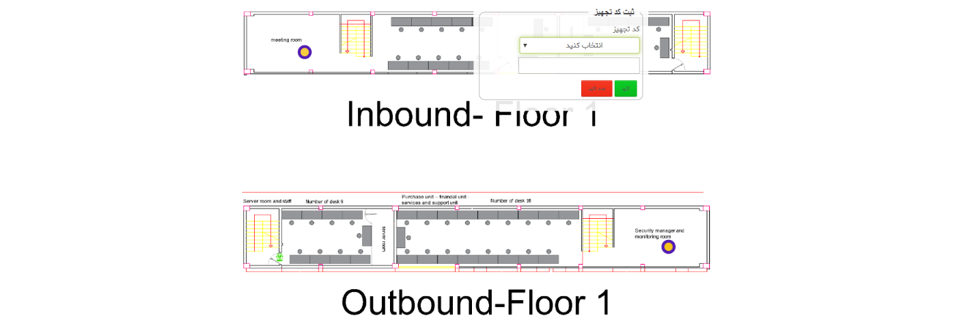

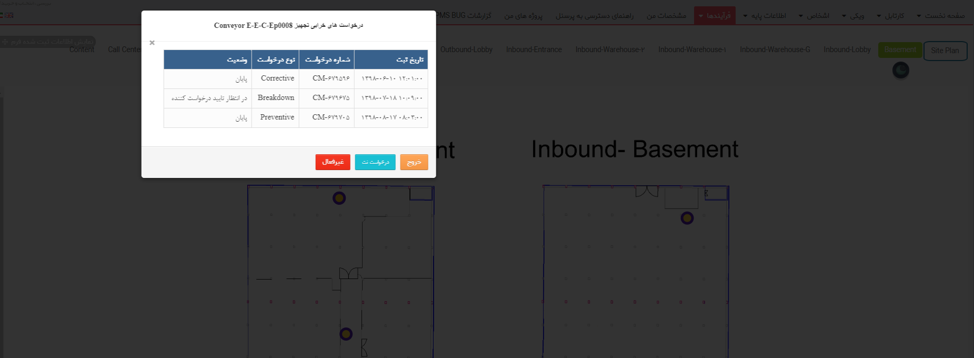

- Ability to register and edit Exact location of equipment on maps Viewing the status of requests and creating a new request Graphically

- Determination performance of technical forces Based on the planning of repair activities

- Separation of action activities into electrical and mechanical types and the possibility of determining access levels of observation and registration for specialized groups From personnel

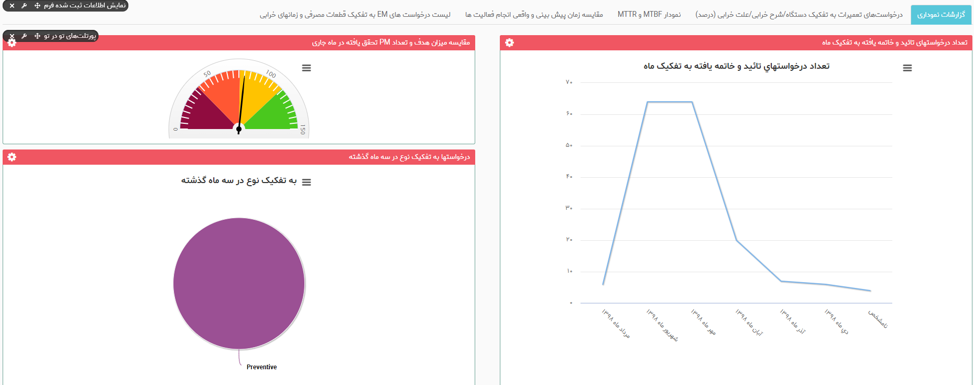

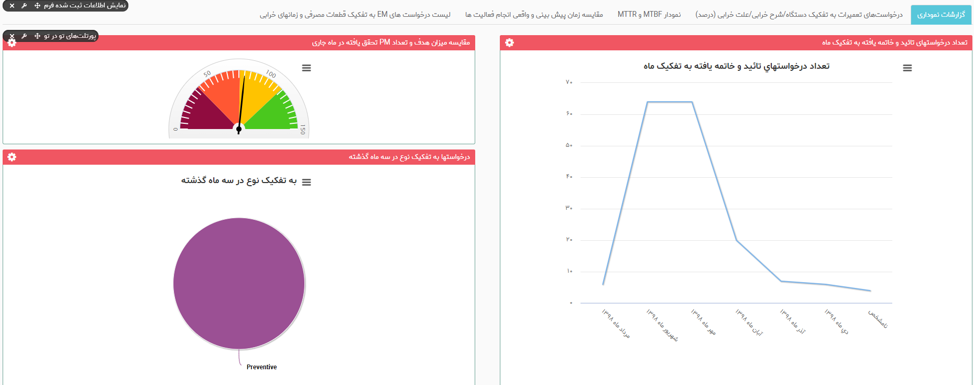

- Possibility Targeting and comparison with realized PMs

- Determination of activities and defects Frequently graphically

- Registering daily checklists and sending alarms if the set time is exceeded

- Automation of registration of preventive requests Systematically and reduce human error

- The possibility of parallel correspondence on the process and recording the opinions of people involved in repairs

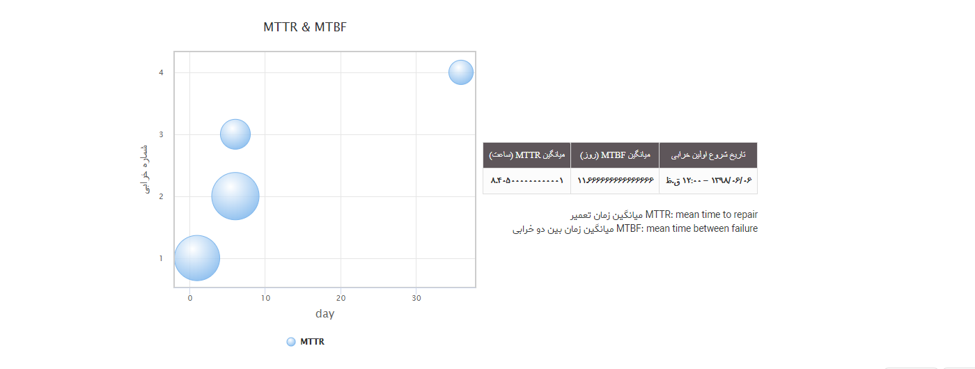

- Ability to analyze equipment maintenance and repairs using diagrams Average time between failures And Average Repair time

Equipment monitor on the map

The ability to record, view and edit equipment and maintenance activities graphically

Administrative reports dashboard

Determining repair costs separately, observing the time of action activities and disruption of operations

Analysis according to the standard indicators of repairs and maintenance

The ability to record, view and edit equipment and maintenance activities graphically

Administrative reports dashboard

Determining repair costs separately, observing the time of action activities and disruption of operations

Analysis according to the standard indicators of repairs and maintenance

Do it If You Feel Like

Products based BPMS

The best ways to track Six Sigma projects Online Support System (Tickets) Orders and Storage Systems The licensing system Registration system of test Suggestions System Collection systems and create databases CRM: Customer Relationship System Communications and office automation systems Register system Employing Systems Subsystems Sale Customer Relationship Marketing System Conference and workshop registration system Accounts management and integration system Portal content management system leave application registration system Loan application registration system Monthly activity registration system Goods registration and ordering system Loan application management system for companies Service Request Registration and Management System (ITIL) PM project management system based on BPMS Repair and maintenance management system Health, safety and environment system Fleet Management System (FMS) Contract management system Cloud LMS system